To increase the ring stiffness, the corrugated pipes surrounded by polypropylene material, come in hand. The cost of manufacturing these corrugated pipes is low due to their hollow structure.

There is no difference between profiled-wall pipes and spiral pipes in the resistance, but the corrugated pipes are better in the production of water tanks due to their lower ring stiffness compared to other double-wall pipes.

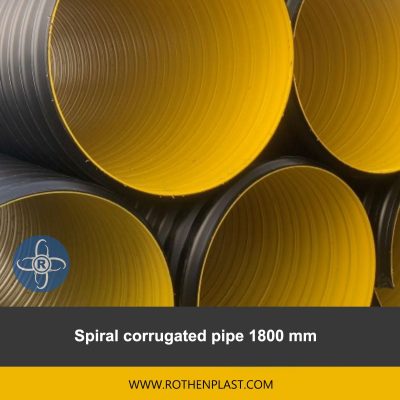

The profiled-wall polyethylene pipes are manufactured in spiral and connected tapes shape.

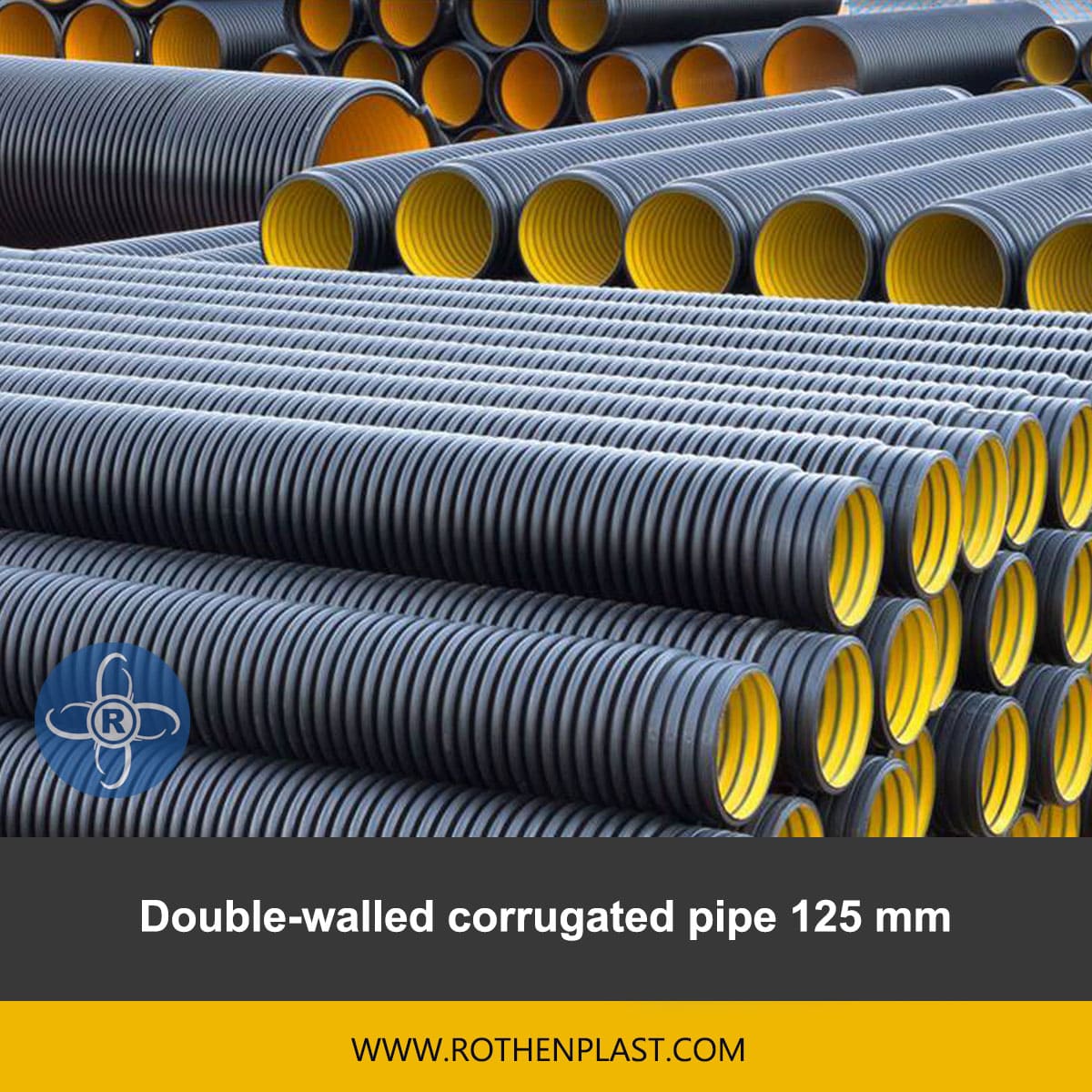

The polyethylene corrugated pipes are produced in three different ring stiffness of 16kN, 31.5kN, and 64kN.

In order to bury the pipe in depths more than 1.5m, the corrugated pipe with ring stiffness more than 16kN should be used.

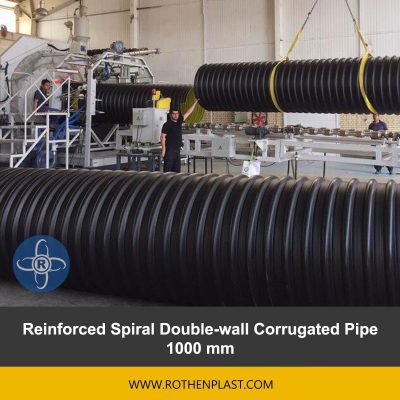

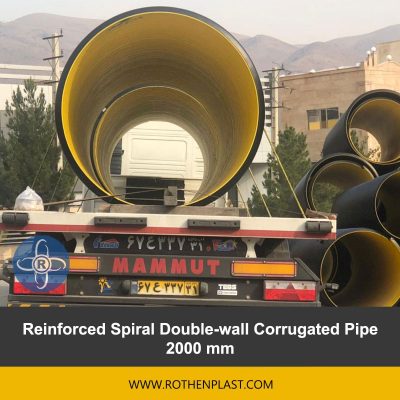

The Rothen Plast production group is the first manufacturer of the double-wall Profiled-wall Polyethylene Pipe in high diameter. This company is also the first company that received the 9116 national standards in Iran, which, by using the most modern technology in the world in accordance with DIN 16961 and ISO 13476, has the ability to manufacture profiled-wall pipes in various diameters from 300mm to 3500mm with 6m in length.

Rothen Plast is one of the largest manufacturers of polyethylene pipes and fittings in large dimension. This company with more than 25 years of experience, by utilizing the most advanced technology in the world and modern European machinery, is able to manufacture double-wall and multi-wall pipes.

The applications of the profiled-wall polyethylene pipes:

The usage of the profiled-wall polyethylene pipes is increasing due to their advantages such as being resistant against corrosion in various environments, their light weight, convenient in transportation, simple production process, possibility of production with high diameters, and etc. This pipe is a good candidate for replacing the other pipes. The double-wall profiled-wall polyethylene pipe, have found various applications due to the strength of the inner and outer layers as well as having high resistance in environments with different properties.

The profiled-wall polyethylene pipes are being used in various projects such as:

-Urban and industrial sewage networks

-Agricultural, urban, and industrial drainage systems

-Water supply and irrigation networks

-Transfer of industrial materials such as acids, bases, salts, and etc.

-Material and liquid storage tank

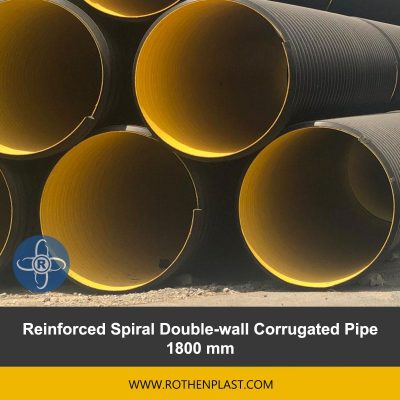

The 1600mm profiled-wall pipe, made of polyethylene with the use of a corrugated duct made of PP polypropylene, has changed the structure of this pipe compared to similar pipes. Also, the period of production of this pipe is different from corrugated and spiral pipes.

The profiled-wall polyethylene pipe has a high resistance against acids and corrosion. Therefore, this pipe has many uses in the coal production, glass production, and similar industries.

The yellow color inside the profiled-wall pipes is optional and it can change to other colors such as white and blue. This color is used to make the process of video insights and amp metrics easier.

The weight of the profiled-wall pipe is much higher than corrugated and spiral ones, because of the structure of this pipe.

The materials used in profiled-wall pipes are high density polyethylene and they are available in PE80-PE100 grades.

The melting temperature of polyethylene materials in the profiled-wall pipe is between 190 ° C to 210 ° C.

The 1600 mm profiled-wall pipes have a very high cross section, therefore, these pipes have a high weight and can be easily connected by electrofusion method.

Using the profiled-wall pipes in projects is very convenient and connecting it by electrofusion is one of the advantages of this pipe compared to similar corrugated pipes.

Another advantage of this pipe is lack of welding line in the inner layer of the pipe and integrated production of it.

This pipe can also be used to transfer seawater to cooling boilers and artificial ponds for shrimp farming.