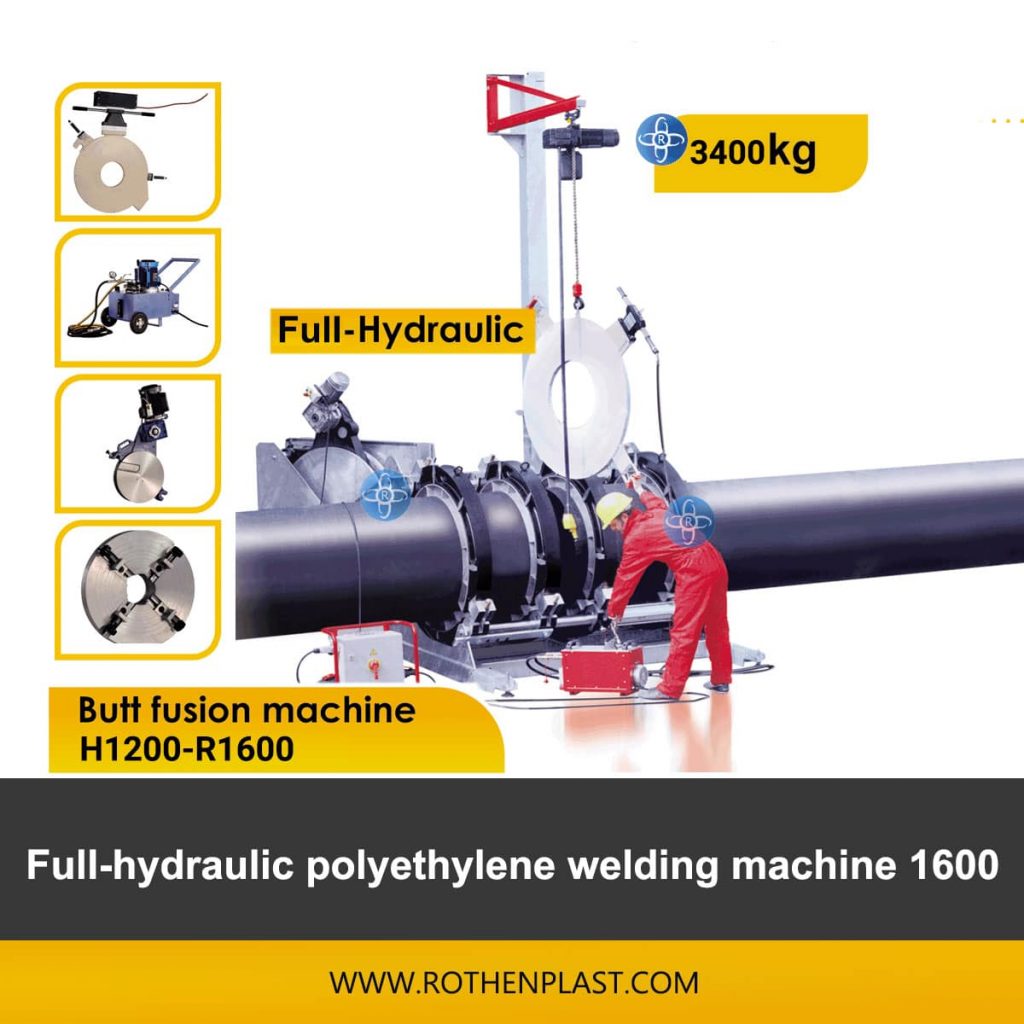

Polyethylene welding machine

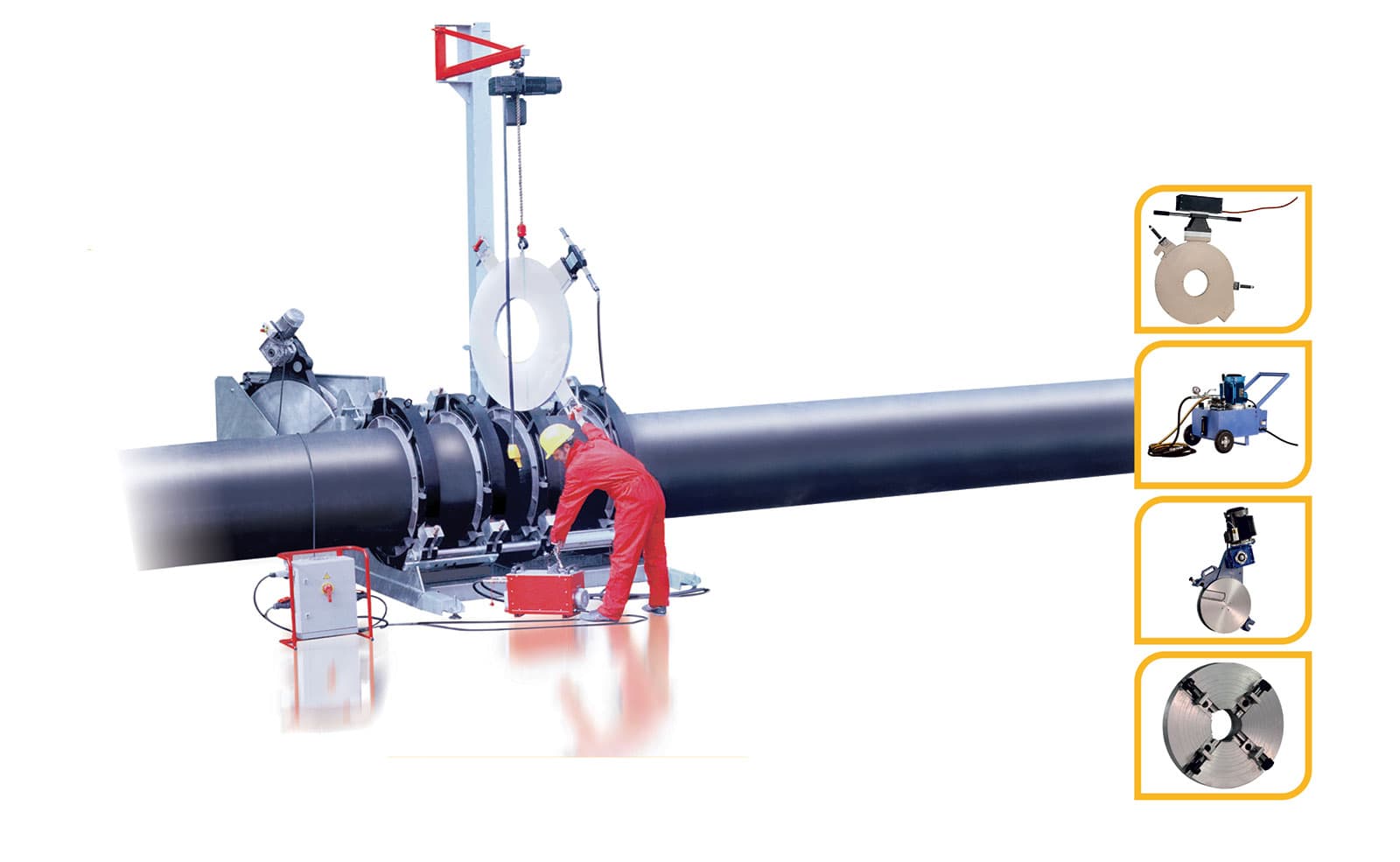

Polyethylene welding machine as the name implies use for polyethylene pipes welding this type of welding is also called butt welding the working method of this type of welding is as follows : at first step put the pipe in the machine and tighten the jaws and then put the milling cutter in the machine and bring the jaws of the machine closer together until the pipes bring to the milling cutter , continue cutting the pipes until the chip comes out as a strip . in the next step the jaws return and pickup the milling cutter , clean the end of both pipes with isopropyl alcohol and put the heater on the machine and bring the jaws together again until the pipes stick to the heater , after the boiling the pipes edges return the jaws back and take off the heater then we glue the pipe together . at this step should enter the required pressure and time according to the welding table to have a complete and standard weld . after the this step put on the pressure but let the pipe stay in the machine until the cooling time is over . after cooling time we can open the jaws and take off the pipe from the machine .

welding machine rothenplast

This welding machine have the models at the bellow :

Handy machine , Semi hydraulic machine , Full hydraulic machine and

CNC machine . ( CNC model have the artificial intelligence )

In the handy machine operator should do the all the works with hands

In the semi hydraulic welding machine , hydraulic pressure is applied with a manual oil pomp and at the full hydraulic machine pressure is applied with a hydraulic power box . at the CNC machine same as the full hydraulic machine pressure is applied with a hydraulic power box but device instead of operator calculate the pressure welding time and the cooling time according to the bar of pipes , PE100 or PE80 and which size of pipe do the weld .

For welding polyethylene Gas pipe should be kind of CNC machine until the Gas company supervisor approves the welding .

CNC polyethylene welding machine of Rotengaran Parse have Gas company approval .

Welding machine have these parts at all :

Chassis of the device , Milling cutter , Heater , Cutter and Heater box , Bites in the different sizes and Flange .

In the Semi hydraulic machine attach a handy oil pomp to chassis

in the full hydraulic machine have power box instead of handy oil pomp

polyethylene milling cutter has two models of drill and gearbox , at the pipe upper than 10 bar usually use of gear box cutter , gear box cutte produce at two model 3phase and 1phase.

Heater too have two models electric heater and gas heater .

The Bites are produce in two models , strip and wide