Rothenplast, one of the most reputable manufacturers of polyethylene welding machines, has introduced a product specifically designed for polyethylene piping projects in Sydney and surrounding areas, utilizing advanced technology and special features. If you are looking for a reliable, efficient, and cost-effective solution for connecting polyethylene pipes, the Rhoten Plast welding machine is the product you need.

Key Features of the RothenPlast Polyethylene Welding Machine

• Durable and High-Quality Design: This machine is built using the latest technologies and is optimized for operation in various climatic and industrial conditions in Sydney.

• High Precision Welding Capability: Rothenplast provides adjustable temperature and pressure settings to ensure precise and uniform welds. This feature guarantees weld quality and prevents common issues such as leaks.

• Ease of Use and Learning: This machine is designed so that even beginners can operate it easily. An easy-to-use interface and practical guide are significant features of this device.

Advantages of Using the RothenPlast Polyethylene Welding Machine in Sydney

1. Reduced Costs and Project Time: With the machine’s high speed and precision, piping projects can be completed in a shorter time, leading to reduced labor and operational costs.

2. Weather Resistance: Rothenplast machines are designed for diverse conditions and can perform excellently in Sydney and surrounding areas.

3. Special Warranty and After-Sales Service: Rothenplast provides a warranty and full support in Sydney, ensuring customers’ peace of mind regarding the durability and performance of the machine.

Technical Specifications of the Rothenplast Polyethylene Welding Machine

• Welding Capability for Various Pipe Diameters: Usable for pipes of different diameters, from the smallest to the largest sizes.

• Advanced Temperature Control Equipment: Rhoten Plast machines are equipped with precise temperature control systems that elevate weld quality to a higher level.

• Advanced Safety System: These machines come with multiple safety systems, including automatic shutoff and overload protection, ensuring user and equipment safety.

Why Rothenplast? The Professionals’ First Choice in Sydney

With years of experience and expertise in producing polyethylene welding equipment, Rothenplast offers a product that effectively meets the needs of contractors in Sydney and Australia. These machines are designed to enhance productivity and reduce costs, fully complying with global standards.

How to Order and Purchase the Machine

For more information or to order the Rothenplast polyethylene welding machine, you can easily make your purchase through our website or by contacting our representatives in Sydney. We are ready to assist you at every step and answer your questions.

If you need any adjustments or further information, feel free to ask!

Sale Welding Machines in Australia

Manual Polyethylene Welding Machine

Butt fusion machine

D32-R110

Application and Features

● Suitable for welding of plastic pipes and/or fittings made of PE, PP,

and PVDF, can be operated in any complex work condition.

● Consists of basic frame, planning tool, heating plate.

● Removable PTFE coated heating plate.

● Electric planning tool.

● Be made of lightweight and high strength material; simple structure,

small and delicate user friendly.

Technical Parameters

| D32-R110 | Model |

| 32.40.50.63.75.90 | Pipe size (mm) |

| 300°C | Heating plate max.Temp. |

| <±10°C | Temp.deviation in surface (170~250 °C) |

| 220 V,50-60 HZ | Working voltage |

| 500 W | Heating plate power |

| 750 W | Planing tool power |

| 1250 W | Total power |

| 34 KG | Weight |

| 70*36*32 | Packing dimension(mm) |

Technical Parameters

| D50-R160 | Model |

| 50.63.75.90.110.125.(140) | Pipe size (mm) |

| 300°C | Heating plate max.Temp. |

| <±10°C | Temp.deviation in surface (170~250 °C) |

| 220 V,50-60 HZ | Working voltage |

| 750 W | Heating plate power |

| 800 W | Planing tool power |

| 1550 W | Total power |

| 50 KG | Weight |

| 75*43*40 | Packing dimension(mm) |

| D63-R200 | Model |

| 63.75.90.110.125.(140). 160. (180) | Pipe size (mm) |

| 300°C | Heating plate max.Temp. |

| <±10°C | Temp.deviation in surface (170~250 °C) |

| 220 V,50-60 HZ | Working voltage |

| 1000 W | Heating plate power |

| 1010 W | Planing tool power |

| 2010 W | Total power |

| 70 KG | Weight |

| 75*52*46 | Packing dimension(mm) |

| D63-R250 | Model |

| (63).(75).90.110.125.(140).160.(180). 200.225 | Pipe size (mm) |

| 300°C | Heating plate max.Temp. |

| <±10°C | Temp.deviation in surface (170~250 °C) |

| 220 V,50-60 HZ | Working voltage |

| 2000 W | Heating plate power |

| 1010 W | Planing tool power |

| 3010 W | Total power |

| 108 KG | Weight |

| 78*56*48 | Packing dimension(mm) |

| D63-R315 | Model |

| (63).(75).90.110.125.(140).160.(180).200.225.250. (280) | Pipe size (mm) |

| 300°C | Heating plate max.Temp. |

| <±10°C | Temp.deviation in surface (170~250 °C) |

| 220 V,50-60 HZ | Working voltage |

| 2500 W | Heating plate power |

| 1010 W | Planing tool power |

| 3510 W | Total power |

| 140 KG | Weight |

| 78*65*61 | Packing dimension(mm) |

Half-Hydraulic Polyethylene Welding Machine

Butt fusion machine

Half-Hydraulic

NH50-R160

Application and Features

● Using cases: this machine is used in sewerage systems, especially in butt

weld Polyethylene PE 63,PE 80,PE100

●Qualifications:welding abilities of polyethylene pipes in

50-63-75-90-110-125-(140) Sizes in 2-2/5-3/2-4-6-10-16 atmospheric pressure

● Machine dimensions : 32*40*35

● Wight : 83 kg

● Accessories:1-Hand Power hydraulic 2-Electric heater 750 w 3-Shaver

4-Regulative Clamps 5-Roller, guiding wheel calibration certificate

Butt fusion machine

Half-Hydraulic

NH63-R200

Application and Features

● Using cases: this machine is used in sewerage systems, especially in

butt weld Polyethylene PE 63,PE 80,PE100

●Qualifications:welding abilities of polyethylene pipes in

63-75-90-110-125-(140)-160-(180) Size in 2-2/5-3/2-4-6-10-16 atmospheric

pressure

● Machine dimensions : 35*40*35

● Wight : 91 kg

● Accessories:1- Hand Power hydraulic 2-Electric heater 1000 w 3-Shaver

Butt fusion machine

Half-Hydraulic

NH63-R250

Application and Features

● Using cases: this machine is used in sewerage systems, especially in butt

weld Polyethylene PE 63,PE 80,PE100

●Qualifications:welding abilities of polyethylene pipes in

(63)-(75)-90-110-125-(140)-160-(180)-200-225 Sizes in 2-2/5-3/2-4-6-10-16

atmospheric pressure

● Machine dimensions : 35*40*35

● Wight :168 kg

● Accessories:1- Hand Power hydraulic 2-Electric heater 2000 w 3-Shaver

4-Regulative Clamps 5-Roller, guiding wheel calibration certificate

Butt fusion machine

Half-Hydraulic

NH63-R315

Application and Features

● Using cases: this machine is used in sewerage systems, especially in

butt weld Polyethylene PE 63,PE 80,PE100

●Qualifications:welding abilities of polyethylene pipes in

(63)-(75)-90-110-125-(140)-160-(180)-200 225-250-(280) Size in

2-2/5-3/2-4-6-10-16 atmospheric pressure

● Machine dimensions : 35*40*35

● Wight : 200 kg

● Accessories:1- Hand Power hydraulic 2-Electric heater 2500 w 3-Shaver

4-Regulative Clamps 5-Roller, guiding wheel calibration certificate

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

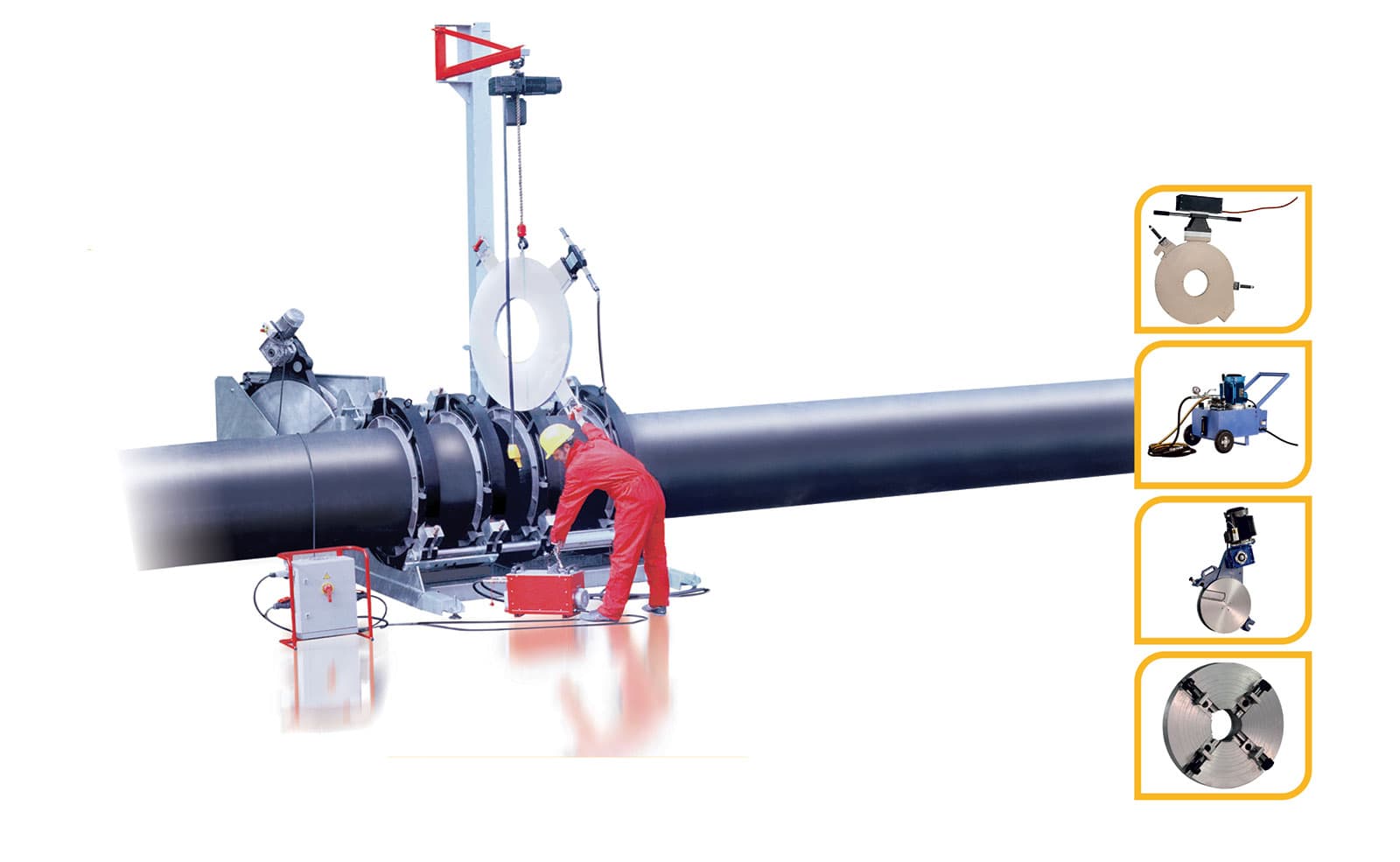

Full-Hydraulic Polyethylene Welding Machine

Butt fusion machine

H50-R160

Application and Features

● Suitable for butt welding of plastic pipes and/or fittings made of PE, PP

and PVDF, in worksite or workshop.

● Consists of basic frame, hydraulic unit, planning tool, heating plate,

Support for planning tool & heating plate, and optional parts.

● Removable PTFE coated heating plate.

● Electrical planning tool.

● Be made of lightweight and high strength material; simple structure,

small and delicate user friendly

●Low starting pressure ensures reliable welding quality of small pipes

●Changeable welding position enables to weld various fittings more easily.

●Separate two-channel timer records time in soaking and cooling phases.

●High-accurate and shockproof pressure meter indicates clearer readings.

| H50-R160 | Model | |

| 50.63.75.90.110.125.(140) | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 220 V, 50-60 HZ | Working voltage | |

| 750 W | Heating plate power | |

| 800 W | Planing tool power | |

| 750 W | Hydraulic unit power | |

| 2300 W | Total power | |

| 110 KG | Weight | |

| 160*90*60 | Frame | Packing

dimension (mm) |

| 51*40*55 | Support | |

| 56*31*32 | Hydraulic unit | |

| H63-R200 | Model | |

| 63.75.90.110.125.(140).160. (180) | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 220 V, 50-60 HZ | Working voltage | |

| 1000 W | Heating plate power | |

| 1010 W | Planing tool power | |

| 750 W | Hydraulic unit power | |

| 2760 W | Total power | |

| 118 KG | Weight | |

| 115*58*48 | Frame | Packing

dimension (mm) |

| 61*52*62 | Support | |

| 56*31*32 | Hydraulic unit | |

Butt fusion machine

H63-R250

Application and Features

● Suitable for butt welding of plastic pipes and/or fittings made of PE,PP,

and PVDF in worksite or workshop.

● Consists of basic frame, hydraulic unit, planning tool, heating plate,

Support for planning tool & heating plate, and optional parts.

● Removable PTFE coated heating plate.

● Electrical planning tool.

● Be made of lightweight and high strength material;simple structure,

small and delicate user friendly.

●Low starting pressure ensures reliable welding quality of small pipes

●Changeable welding position enables to weld various fittings more easily.

●Separate two-channel timer records time in soaking and cooling phases.

●High-accurate and shockproof pressure meter indicates clearer readings.

| H63-R250 | Model | |

| (63).(75).90.110.125.(140). 160.(180). 200.225 | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 220 V,50-60 HZ | Working voltage | |

| 2000 W | Heating plate power | |

| 1010 W | Planing tool power | |

| 750 W | Hydraulic unit power | |

| 3760 W | Total power | |

| 196 KG | Weight | |

| 120*70*56 | Frame | Packing

dimension (mm) |

| 80*54*62 | Support | |

| 56*31*32 | Hydraulic unit | |

| H63-R315 | Model | |

| (63).(75).90.110.125.(140).160.(180).200.225.250.(280) | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 220 V,50-60 HZ | Working voltage | |

| 2500 W | Heating plate power | |

| 1010 W | Planing tool power | |

| 750 W | Hydraulic unit power | |

| 4260 W | Total power | |

| 228 KG | Weight | |

| 120*70*65 | Frame | Packing

dimension (mm) |

| 73*40*73 | Support | |

| 56*31*32 | Hydraulic unit | |

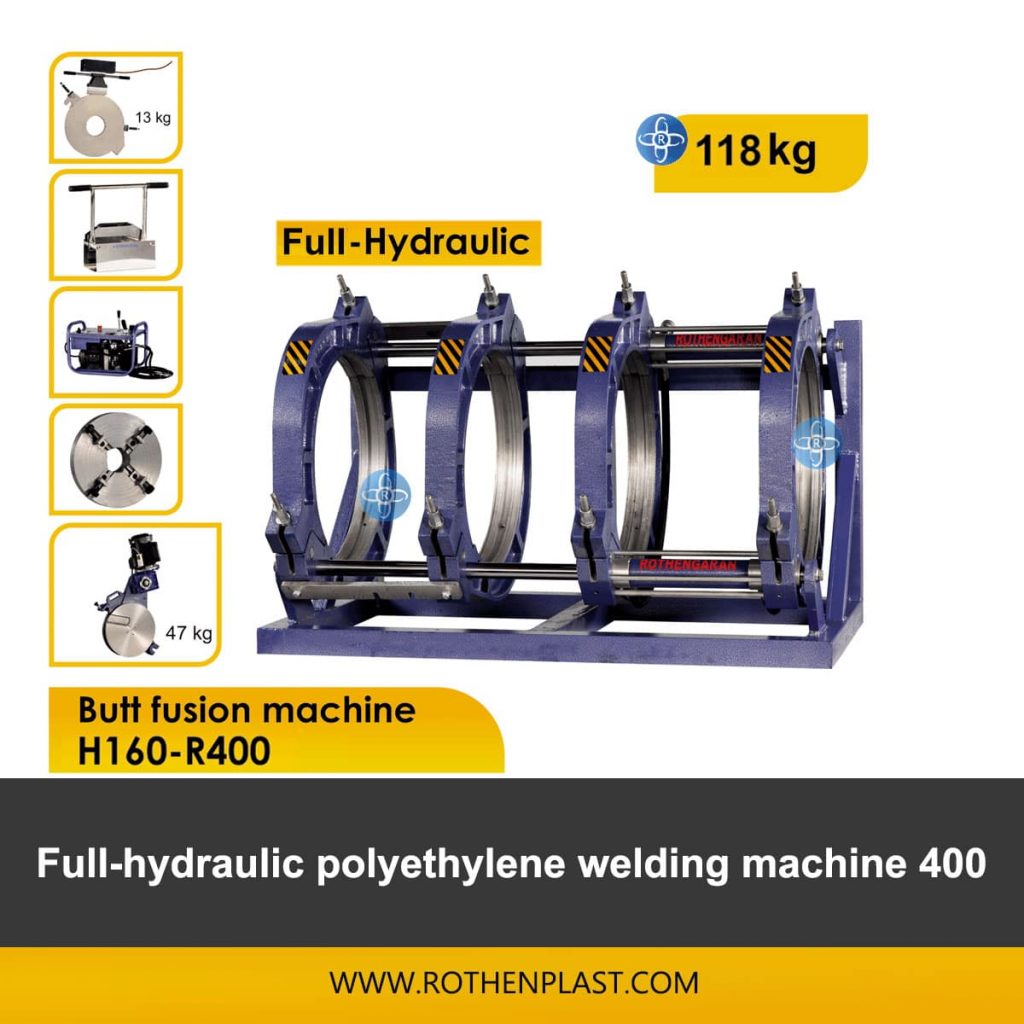

Butt fusion machine

H160-R400

Application and Features

● Suitable for butt welding of plastic pipes and/or fittings made of PE,

PP,and PVDF in worksite or workshop.

● Consists of basic frame,hydraulic unit,planning tool,heating plate,

Support for planning tool & heating plate,and optional parts.

● Removable PTFE coated heating plate with high accurate

temperature control system.

● Electrical planning tool with safety limit switch..

● Be made of lightweight and high strength material;

● Designed with a clamp opening angle of 45 degree.

● Low starting pressure and high reliable seal structure.

● Changeable welding position enables to weld various fittings easier.

● Separate two-channel timer records time in soaking and cooling phases.

● High-accurate and shockproof pressure meter indicates clearer readings.

| H160-R400 | Model | |

| (160).(180).200.225. 250.(280).315.355 | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 220 V,50-60 HZ | Working voltage | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 3000 W | Heating plate power | |

| 1500 W | Planing tool power | |

| 750 W | Hydraulic unit power | |

| 5250 W | Total power | |

| 303 KG | Weight | |

| 120*84*88 | Frame | Packing

dimension (mm) |

| 87*38*98 | Support | |

| 56*31*42 | Hydraulic unit | |

| H250-R500 | Model | |

| 250.(280).315.355.400.450. | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 380V,50-60 HZ | Working voltage | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 4000 W | Heating plate power | |

| 1500 W | Planing tool power | |

| 1500 W | Hydraulic unit power | |

| 7000 W | Total power | |

| 425 KG | Weight | |

| 125*85*88 | Frame | Packing

dimension (mm) |

| 95*65*116 | Support | |

| 100*53*68 | Hydraulic unit | |

| H315-R630 | Model | |

| 315.355.400.450.500.560 | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 380 V,50-60 HZ | Working voltage | |

| 0-6.3 Mpa | Pressure adjustable ranges | |

| 6000 W | Heating plate power | |

| 1500 W | Planing tool power | |

| 1500 W | Hydraulic unit power | |

| 9000 W | Total power | |

| 587 KG | Weight | |

| 135*94*104 | Frame | Packing

dimension (mm) |

| 116*66*132 | Support | |

| 100*53*68 | Hydraulic unit | |

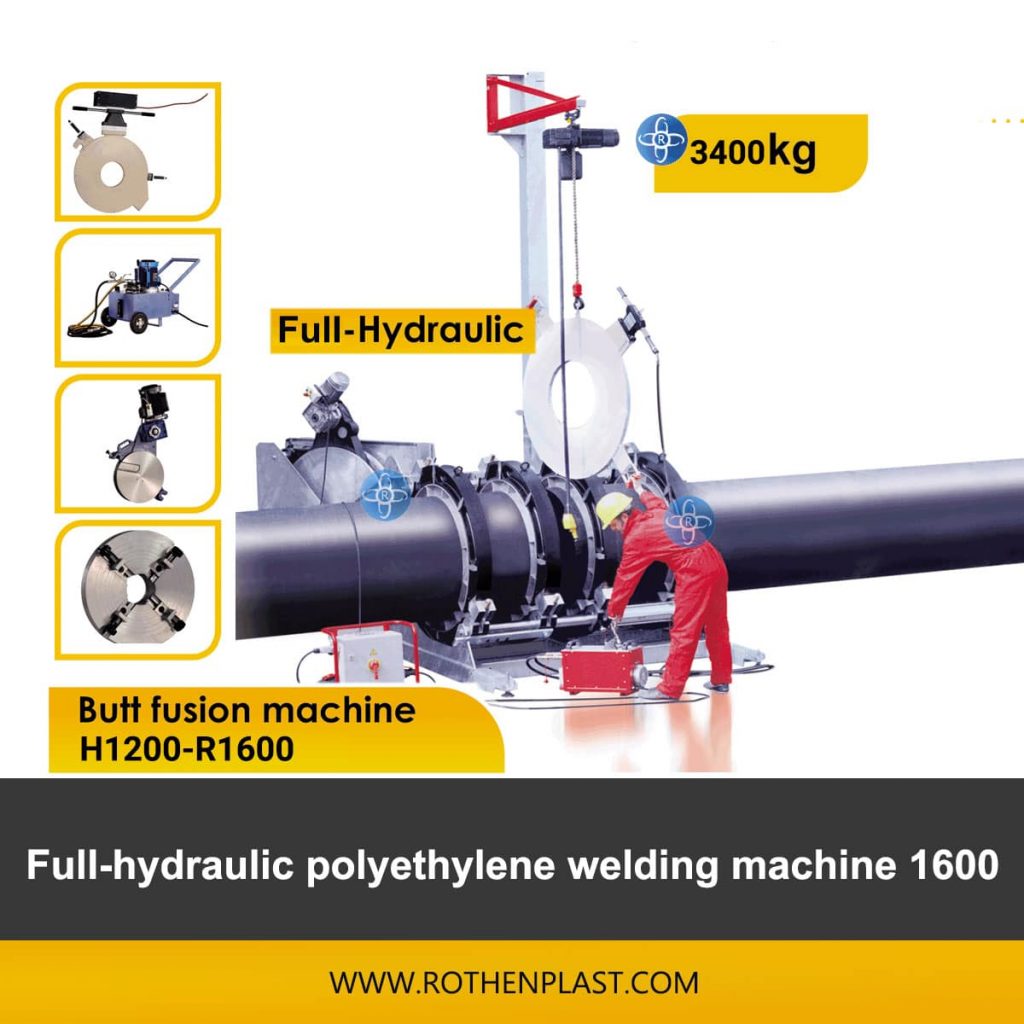

Butt fusion machine

H400-R800

Application and Features

● Suitable for butt welding of plastic pipes and/or fittings made of

PE,PP,and PVDF in worksite or workshop.

● Consists of basic frame,hydraulic unit,planning tool,heating plate,

Support for planning tool & heating plate,and optional parts.

● Removable PTFE coated heating plate with high accurate temperature

control system.

● Electrical planning tool with safety limit switch enables to start it only

when it is locked in operation osition. Made of lightweight and high

strength material. Designed with a clamp opening angle of 45 degree.

●Low starting pressure and high reliable seal structure.

●Changeable welding position enables to weld various fittings easier.

●Separate two-channel timer records time in soaking and cooling phases.

●High-accurate and shockproof pressure meter indicates clearer readings.

| H400-R800 | Model | |

| 400.450.500.560.630.710 | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-16 Mpa | Pressure adjustable ranges | |

| 380 V,50-60 HZ | Working voltage | |

| 8000 W | Heating plate power | |

| 2200 W | Planing tool power | |

| 500 W | Crane power | |

| 10700 W | Total power | |

| 1294 KG | Weight | |

| 166*130*130 | Frame | Packing

dimension (mm) |

| 110*48*174 | Support | |

| 127*53*70 | Hydraulic unit | |

| 73*44*52 | Electric crane | |

| 193*66*42 | Crane pillar | |

| H500-R1000 | Model | |

| 500.560.630.710.800.900 | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-16 Mpa | Pressure adjustable ranges | |

| 380 V,50-60 HZ | Working voltage | |

| 11000 W | Heating plate power | |

| 3000 W | Planing tool power | |

| 1000 W | Crane power | |

| 15000 W | Total power | |

| 1900 KG | Weight | |

| 255*180*170 | Frame | Packing

dimension (mm) |

| 140*110*155 | Support | |

| 127*53*70 | Hydraulic unit | |

| 76*51*64 | Electric crane | |

| 193*66*42 | Crane pillar | |

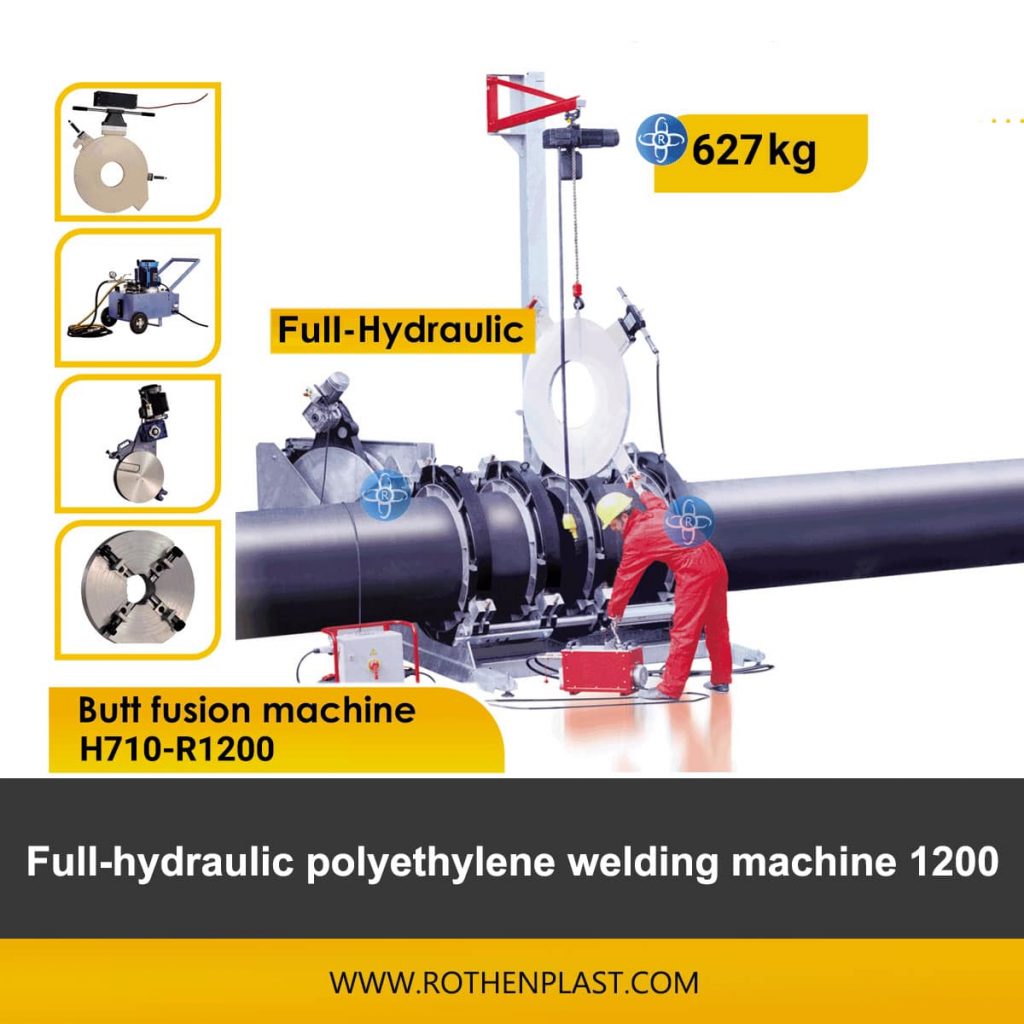

| H710-R1200 | Model | |

| 710.800.900.1000 | Pipe size (mm) | |

| 300°C | Heating plate max.Temp. | |

| <±7°C | Temp.deviation in surface (170~250 °C) | |

| 0-16 Mpa | Pressure adjustable ranges | |

| 380 V,50-60 HZ | Working voltage | |

| 15000 W | Heating plate power | |

| 3000 W | Planing tool power | |

| 1000 W | Crane power | |

| 19000 W | Total power | |

| 2500 KG | Weight | |

| 302*222*235 | Frame | Packing

dimension (mm) |

| 192*142*255 | Support | |

| 127*53*70 | Hydraulic unit | |

| 76*51*64 | Electric crane | |

| 312*77*85 | Crane pillar | |

Butt fusion machine - Workshop welding machine for waste water

Butt fusion machine

Workshop Welding Machine For Wastes Water

DF50-R160

Application and Features

● Suitable for lengthening short injection molded fitting in

a workshop or produce an integrated fittings.

● Also used to install drainage system in building. Specially

designed clamps according to features in structure and

dimension of fitting in drainage system.

● Removable PTFE coated heating plate with separate

temperature controlling system.

● Electric planning tool with safety limit switch enables it to be

started only when it is locked in operation position.

●Spring manometer provides correct welding pressure.

●Pivoting planning tool and heating plate bring convenience to

placing and removing.

●Mechanical lock to maintain welding pressure.

Optional parts:

●Various special clamps for installation.

●Of drainage system in building.

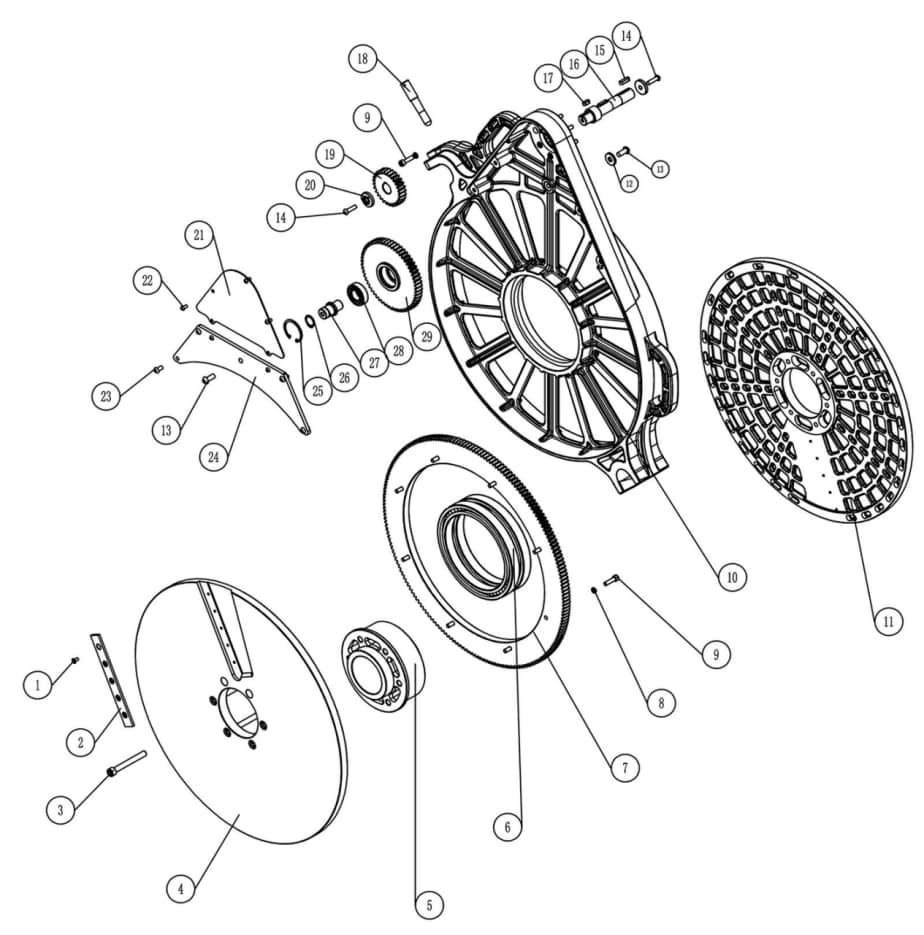

Butt fusion machine - Workshop Fitting machines

Butt fusion machine

Workshop Fitting Machines

HZ 90-R315 HZ 250-R450 HZ 315-R630

Application and Features

● Suitable for fabricating elbow,tee,cross and Y shape (45 and 60)

fittings of PE,PP,PVDF in workshop.Also used to lengthen the

injection moulded fitting or make the integrated fitting.

●Integrated structure,Nothing remains but to choose the different

special clamps while fabricating different fittings.

● Removable PTFE coated heating plate.

● Electric planning tool with safety limit switch.

● Low starting pressure and high reliable seal structure.

●Separate two-channel timer records times in soaking and

cooling phases. High-accurate and shockproof pressure

meter indicates clearer readings.Digital pressure meter is

installed on machines above HZ315 pivoting planning

tool and heating plate bring convenience to placing

and removing. Hz450 & HZ630 linear guide ways are

equipped with heating plate and planning tool.

Optional parts:

●Special clamps for welding flange stub.

● Special clamps for short spigot fitting.

●Special clamps for welding Y shape (45° and 60°) fittings.

| HZ 315-R630 | HZ 250-R450 | HZ 90-R315 | Model |

| 315.355.400.450.500.560 | 250.(280).315.355.400 | 90.110.125.(140).160. (180).200.225.250.(280) | Pipe size (mm) |

| 0-90° Elbow , tee , cross , 45° , 60° Wyes (optional parts should be used) | Application | ||

| 270°C | 270°C | 270°C | Heating plate max.Temp. |

| <±7°C | <±7°C | <±7°C | Temp.deviation in surface (170~250 °C) |

| 380 V, 50 HZ | 380 V, 50 HZ | 380 V, 50 HZ | Working voltage |

| 8000 W | 6000 W | 5000 W | Heating plate power |

| 3000 W | 2200 W | 1500 W | Hydraulic unit motor power |

| 4000 W | 4000 W | 1000 W | Planing tool motor power |

| 15000 W | 12200 W | 7500 W | Total power |

| 3510 Kg (Don’t include optional parts) | 2850 Kg (Don’t include optional parts) | 1884 Kg (Don’t include optional parts) | Weight |

Butt fusion machine - Automatic welding machines

Butt fusion machine

Automatic Welding Machines

H-CNC63-R250

Application and Features

● Control system of microcomputer can detect automatic welding process.

● Automatic butt fusion welding machine can be used in at worksite and workshop.

●Suitable for butt welding of plastics pipes and fittings made of PE,PP,and PVDF.

●Removable PTFE coated heating plated with high accuracy temperature control system

● Main part of basic frame is made out of Aluminum alloys,light and handy structure,

convenient to use.

● Optional models: H-CNC250,H-CNC315

Advantages:

Computer control is according to national standard GB/T20674’1

At the predetermined parameters range,all phases of butt welding process are

controlled automatically.

Error analysis system will recognize the error with predetermined parameters.

Computer can save 350 pieces of welding records,and input the records to computer.

With mini printer, can review welding records welding process at site.

| H-CNC63-R250 | Model |

| (63).(75).90.110.125.(140).160.(180).200.225 | Welding ranges (mm) |

| 300°C | Heater max,Temp. |

| <±5°C | Temp.deviation in surface (170~250 °C) |

| 0~6 .3 Mpa | Pressure indicate ranges |

| 220 V , 50 HZ | Working voltage |

| 2100 W | Heater power |

| 1100 W | Trimmer power |

| 1500 W | Hydraulic unit power |

| 4700 W | Total power |

| 143 KG | Total weight |

Butt fusion machin - Repair welding machine

Butt fusion machin

Repair welding machine

Rapairing machines developed as completion of 250,315,355

and 500 machines.

Three clamps built on two hydraulic cylinders compose the

machine ; one clamp is also easily removable.

The best solution to work in cramped spaces.

These machines can be equipped with the same components

(heating mirror, facing tool,hydraulic unit and reducing inserts)

of the corresponding HT models.

Hydraulic Unit

Hydraulic Unit

This machine is part of the PE welding equipment.

The machine is used to move hydraulic jacks and has two

hydraulic hoses (sweep).

● compact construction with protection frame.

● fine adjustment of pressure.

● clearly visible pressure gauge with precision scaling (0-160 bar)

● high pressure constance during cooling phase.

● fix attached hydraulic hoses.

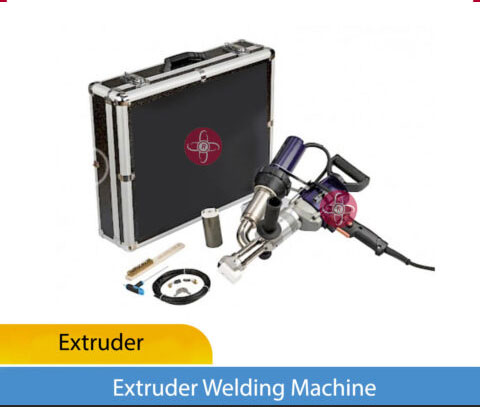

Extruder (Wire)

Extruder (Wire)

Manual and wire extruder welding machine is used for welding spiral and polyethylene carbide pipes as well as for repair and fabrication of polyethylene tanks.

Equipped with German bosch warm air blower with 2000 watts to boost working surface.

Equipped with digital temperature display.

Flexible cylinder round element with 1100 watts and thermocouples.

Low-power motor to 1010 watts.

PTF shoe in different designs depending on the type of user.

Equipped with 3, 4 and 5 mm wire inlets.

Dispensing materials 2 to 3 kg per hour.

With retainer base and adjustable handle.

Thermocouple for temperature regulation.

Total weight with air blower 7.5 kg.

| Extruder Wire | Model |

| 2.5 KG/H | Welding Capacity |

| 3.4.5 mm (PE.PP.PVDF) | Max diametre rod |

| 54*34*35 | Dimension |

| 1100 W | Heating extruder |

| 2000 W | Heating air |

| 1010 W | Drive |

| 300 1/Min | Air requirement |

| 2000 W | Hot air blower |

| 7.5 KG | Weight |

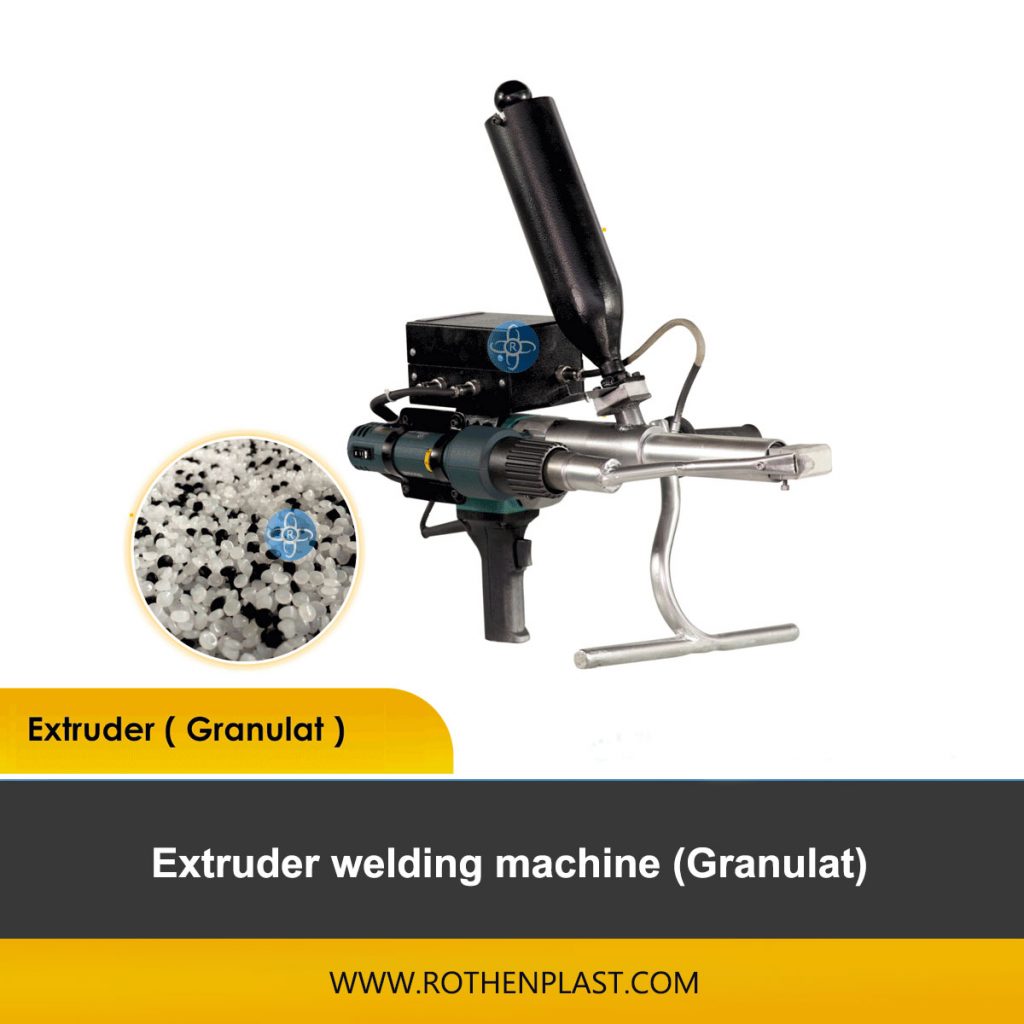

Extruder ( Granulat )

Manual and wire extruder welding machine is used for welding spiral and polyethylene carbide pipes as well as for repair and fabrication of polyethylene tanks.

Equipped with German bosch warm air blower with 2000 watts to boost working surface.

Equipped with digital temperature display.

Flexible cylinder round element with 1100 watts and

thermocouples.

Low-power motor to 1010 watts.

PTF shoe in different designs depending on the type of user.

Dispensing materials 4 to 5 kg per hour.

With retainer base and adjustable handle.

Thermocouple for temperature regulation.

Total weight with air blower 10 kg.

Single phase AC current and 220V voltage.

4000 Watt power consumption.

| Extruder Granulat | Model |

| 4 KG/H | Welding Capacity |

| Granulat (PE.PP.PVDF) | Max diametre rod |

| 57*34*60 | Dimension |

| 1100 W | Heating extruder |

| 2000 W | Heating air |

| 1010 W | Drive |

| 300 1/Min | Air requirement |

| 2000 W | Hot air blower |

| 10 KG | Weight |